Reading time 2 minutes.

SOFIT, a family-run business founded at the end of the 20th century, was among the first in the world to manufacture glass nail files. That has given us the wealth of experience we need to combine traditional glassmaking methods with the latest tech and fashion trends.

Everything involved in the production of our glass nail files happens under one roof. From sourcing the raw glass to the final packaging, all stages of the manufacturing process take place in our glassworks in Městec Králové. A lot of the equipment we use is actually from our own design workshop.

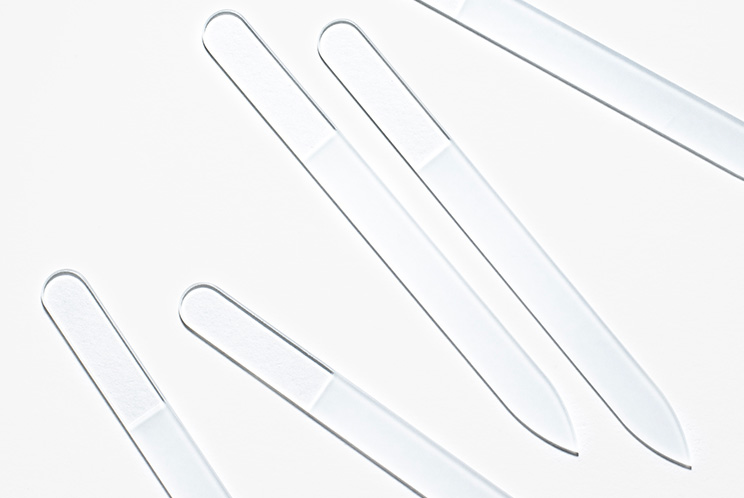

The base material used in the production of SOFIT glass nail files is sheet glass made from natural ingredients – glass sand, soda, limestone, and dolomite. This glass is the same kind as you have in your windows and doors, and is perfectly safe. Once we receive the sheet glass from our supplier, we cut it into smaller strips on our special cutting table. Each strip is sized with just the right width for what will become the nail files.

The next step in the manufacturing process is to expose these glass strips to an acid mixture under carefully controlled conditions. This gives the surface a rough texture directly within the glass itself, so there is no risk of abrasive grains falling off, as can happen with metal, paper, or cheaper glass files where the grains are applied onto the surface.

The roughness of the surface comes from the type of glass itself, so this is not something we can change much. To offer files with different levels of roughness, we use glass that has a naturally textured surface. This way, we make products that are perfect for pedicures or men’s manicures.

After etching, the glass is washed and dried, then the strips are cut into smaller pieces that are shaped into individual nail files. Although this grinding is done by hand, we use specially designed tools to make sure each file is shaped correctly for the given model range.

The final step after shaping is ion-exchange tempering. This significantly increases the strength and durability of SOFIT glass nail files. Once this last stage is complete and the files have been given their characteristic qualities, many of them are embellished further with one of our available decorative techniques.